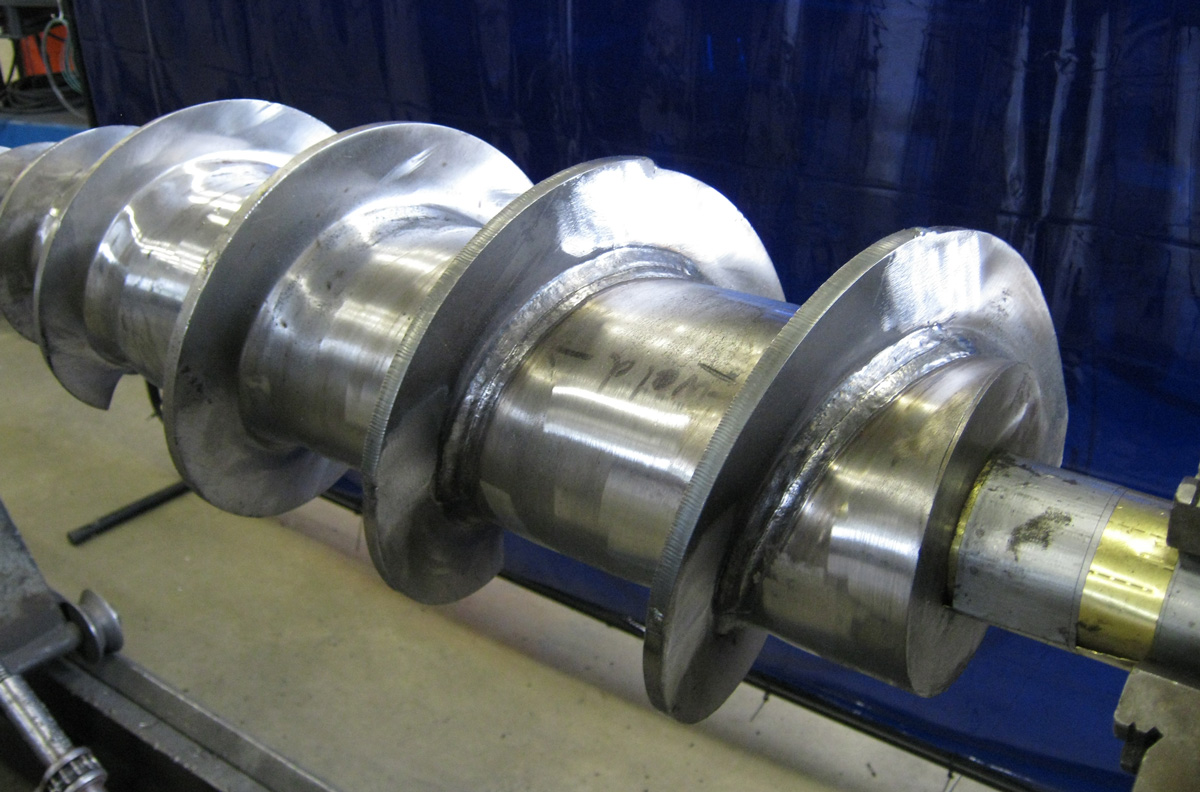

Case Study: Improving Auger Flighting Quality for Industrial Mixing Equipment

A manufacturer of industrial mixing, blending, and dispersion equipment challenged Falcon after running into issues with a recent batch of flighting, to improve the surface quality of the new designs. The company had worked with Falcon successfully in the past, but this time the parts didn’t meet expectations. Instead of letting the challenge disrupt production, both teams came together to uncover what went wrong, clarify the application details, and make it right.

The Challenge

The manufacturer needed flights with a polished, defect-free finish to ensure smooth assembly and minimize labor-intensive post-processing. The original batch contained surface imperfections that required manual polishing — a tedious process that risked thinning the metal and slowing production. For a business that relies on tight tolerances and efficiency, this extra step added unnecessary delays and frustration.

Falcon’s Approach

Falcon’s team immediately dug in to understand what happened. After reviewing the design requirements and production process, Falcon’s team identified ways to refine tooling and adjust fabrication steps for this particular application. Rather than just replacing the parts, Falcon made sure the next batch reflected a shared understanding of the product’s end use and finished quality goals.

Test pieces were produced to verify the improvements before proceeding with the full run. The revised flights were then remanufactured quickly and delivered on schedule — defect free, consistent, and ready to install.

The Results

- Improved quality: The replacement flights arrived with a smooth, clean finish, eliminating the need for manual polishing.

- Saved time and labor: The customer’s team could stay focused on production, not rework.

- Reinforced trust: By handling the issue transparently and taking ownership of the solution, Falcon strengthened a partnership built on integrity and loyalty.

As one executive vice president put it:

“We greatly appreciate your efforts to resolve this matter by providing replacement flights that meet our expectations. The replacement flights were some of the best we’ve seen and exactly what we need for our application.”

Partner with Falcon

Even with the best planning and experience, challenges can arise in manufacturing. What matters most is how those challenges are handled. At Falcon, we take pride in working closely with customers to understand their needs, communicate openly, and stand behind every product we deliver.

Contact us online at (888) 993‑2526 to see how Falcon can help your operation run effortlessly with high‑performing, defect‑free components.