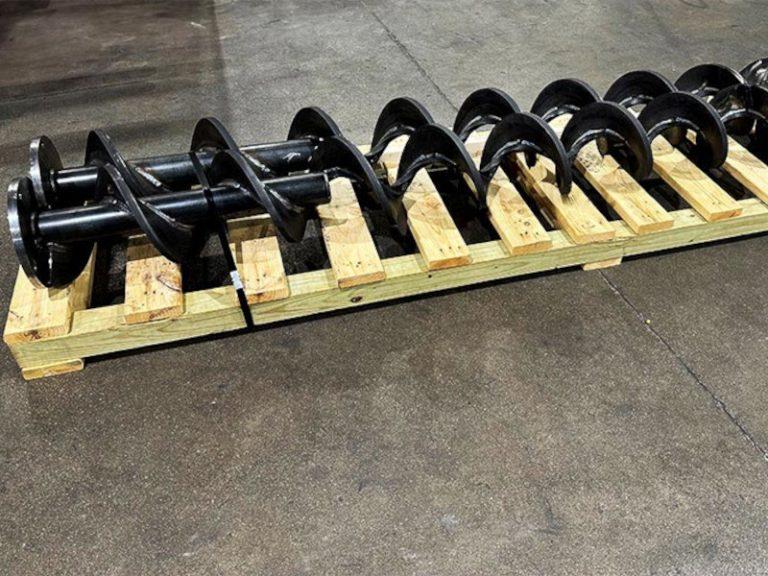

Complete Screw Systems

Falcon’s goal is to provide our customers with a complete solution. We have the machining and assembly capabilities to manufacture even the most complicated and demanding conveyor augers and mixing screws. We can take on any project, even those our competitors consider impossible. With our 40+ years of forming experience, custom-built equipment, and experienced employee-owners, we can produce greater uniformity between pieces and hold tighter tolerances even for very large products.

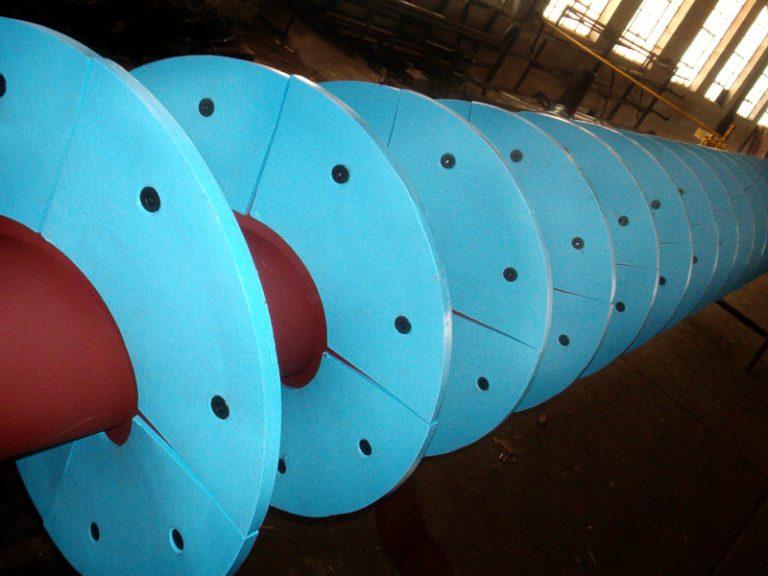

We produce complete screw weldments or augers by mounting helical or sectional flight to a shaft or pipe and add ancillary features, such as flanges, hub, posts, or other means to turn the screw, as well as machine-in keyways and other devices into the shaft. These can vary widely from a simple pipe with the ends bushed and drilled to a long, tapered solid shaft with an intricately machined drive coupling.

Across our two locations, we house equipment for CAD and CNC machining the most challenging conveyor augers and mixing screws to our customer’s specifications. As a result, Falcon has earned a reputation in the industry for being able to handle tough jobs and do them well. Our locations are equipped with custom-built presses, winding equipment, and machining centers to complete the most complicated jobs.

Our extensive and varied customer base has given us the experience and expertise to manufacture in quantities from intricate one-off projects to large production runs. Falcon’s tight tolerances and experience with a wide variety of materials allow us to offer an economical solution to your needs.

We also provide value-added services such as hard surfacing, polishing, and other surface finishing for clean, durable products. We can also assist with engineering and manufacturing ideas that will save you money and expense based on our 40+ years of flight-forming experience.

Ready to get started?

Falcon Industries offers complete auger flight and customized conveying solutions for various materials in diverse industries. We are one of the most experienced auger and screw manufacturers across industry lines, with years of manufacturing and design experience. For more information about our products and services, or if you’re interested in requesting a quote, don’t hesitate to contact us or request a quote today to get started.